Fabrication Technology Development Branch

(D212)

Provides a variety of fabrication technologies enabling the development of research oriented hardware for aeronautics, space exploration, and scientific programs at Langley Research Center. We develop one-of-a-kind test specimens, employing special fabrication techniques applicable to additive manufacturing, composites, plastics, polymers, and laser ablation.

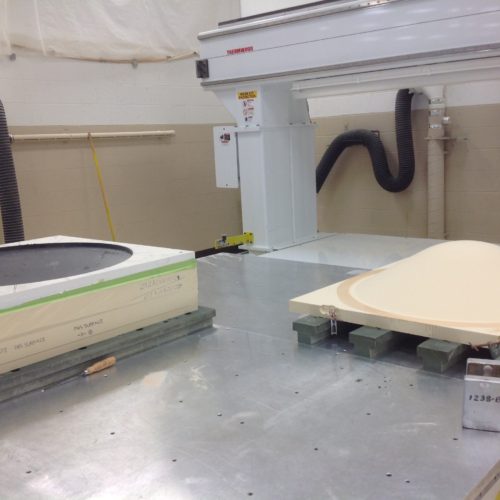

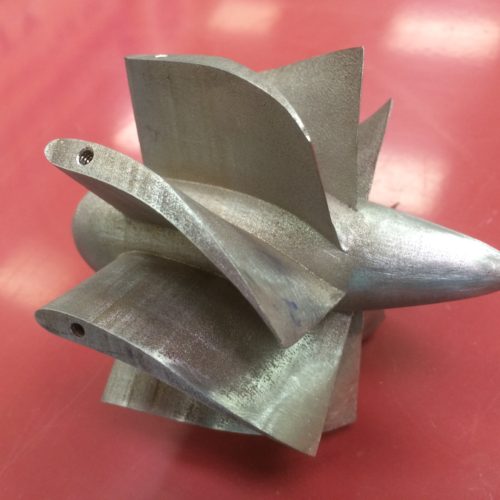

Advanced Manufacturing and Composite Capabilities

- 3 & 5 Axis CNC Machining

- Autoclaves

- Automated Ply Cutter

- Additive Manufacturing Systems – FDM/plastics, SLA/resins, SLM/metallics

and Projet Wax Printing - Brazing

- Composites Processing Lab

- Computer Aided Design (CAD) – Additive Manufacturing

- Coatings/Paint Booths

- Electron Beam Free Form Fabrication System – wire additive

- Freezers – Storage of Prepreg Composite Materials

- Grinding Room

- Instrumentation – Test Articles

- Integrated Structural Assembly of Advanced Composites (ISAAC) housed in

a ISO 7 Cleanroom Cell w/independent temperature and humidity control - Kilns/Ovens

- Large Surface Tables for Layup & Assembly

- Laser Ablation System

- Laser Trackers

- Materials Casting (Ceramic Models/Test Articles)

- Overhead Cranes and Forklifts

- Plastics Room – Adhesives, Resins, Paints, Solvents, etc.

- Test Article and Tunnel Model Fabrication

- Toolomg & Patterns

- Precision Composites Machining

- Classified Work Areas/Cells

Branch Head

Nancy M. H. Holloway

Nancy M. H. Holloway

757-864-7849

Email: Nancy.M.Holloway@nasa.gov

Assistant Branch Head

Kenneth A. Deyerle

757-864-8317

Email: Kenneth.A.Deyerle@nasa.gov